Scooter

Scooter (SHMD-2001)

Key Features

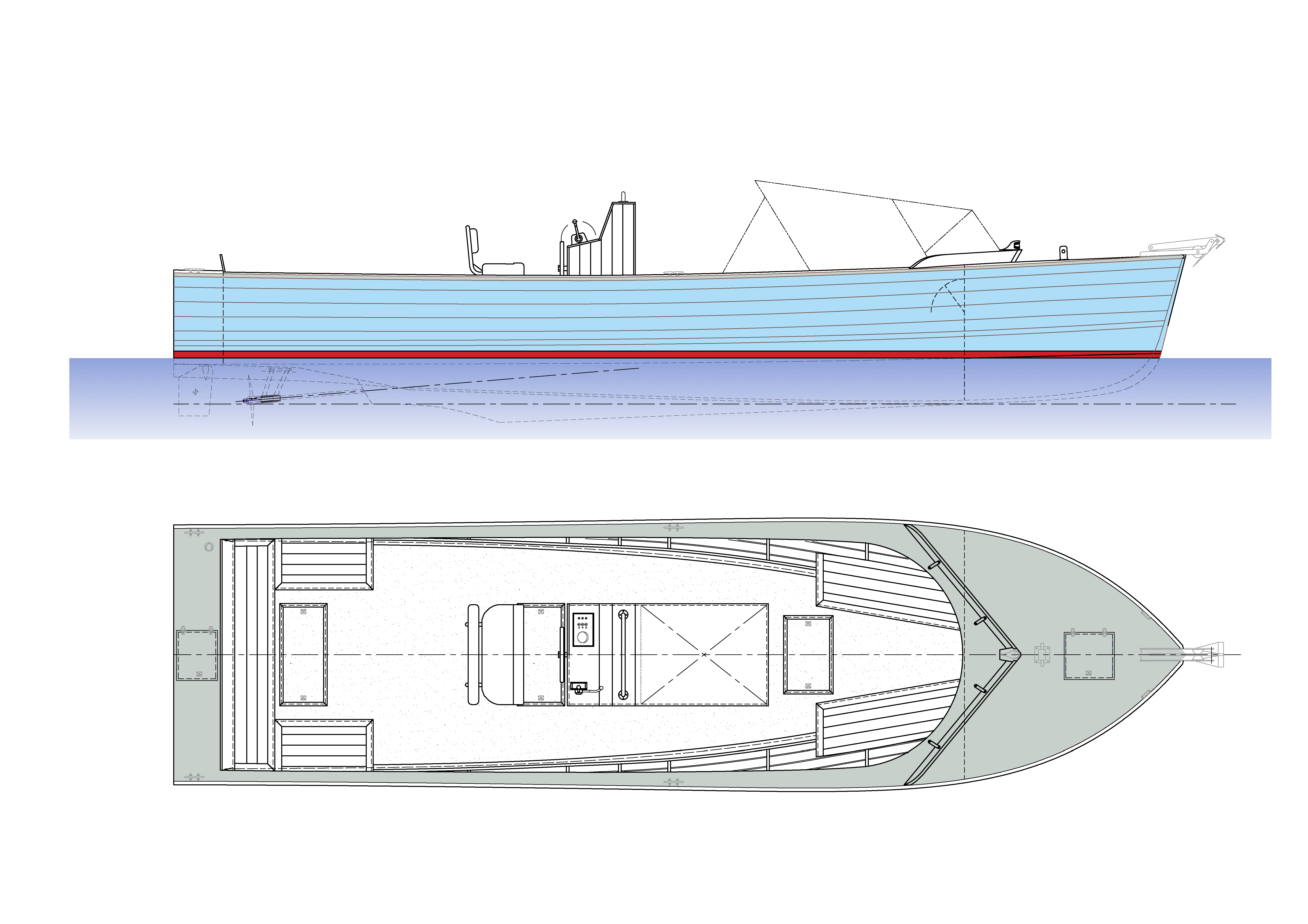

• 24 ft. classic open power launch

• Modern engineering with retro-styling

• Lapstrake construction over a twenty-first century hull

• Economical and powerful - plane faster with less power

| Max Speed (light load) | 20 kts |

| Max Speed (full load) | 18 kts |

| Engine | 1 x Yanmar 4JH45 |

| Power | 45 hp @ 3000 rpm |

| Fuel | 20 gal (diesel) |

| Length | 23.5 ft |

| Beam | 6.2 ft |

| Draft (to skeg) | 1.7 ft |

| Bottom | 2 x 6mm (1/4") layers of laminated marine plywood, covered in 1208 fiberglass cloth, set in epoxy |

| Topsides | 9mm (3/8") layer of glued lapstrake marine plywood |

| Deck | 6mm (1/4") layer of marine plywood |

| Frames & Bulkheads | 19mm (3/4") CNC cut marine plywood (okume) |

| Prop Tunnel | 12mm (1/2") x 25.4mm (1") bead and cove doug fir, or cedar set in 1208 fiberglass on both sides |

| Adhesive | Epoxy |

Description

Scooter is a modestly powered open power launch. Her lapstrake construction intends to break up the slab-sided nature of plywood boat building and accentuate her graceful lines. The double chine hull form allows for a finer entry while still able to keep some spring (convexity) in the forward sections for ease of construction. Her flare forward should keep the ride reasonably dry and the breakwater on the front will shunt whatever water does get on the deck overboard. Additional protection from the elements can be obtained with an optional dodger. The rise of her keel gives the hull bottom a warped plane which initiates planning faster with less power and the prop tunnel keeps the propeller tucked up and (with luck) out of harm's way.

The design centers around cold-molded construction techniques and modern machining practices. All of the frames and longitudinal girders are designed to be CNC cut from 19mm (3/4“) marine plywood; preferably okume. The lapstrake layout has been lofted and the plank pockets included in the cutout of the frames. The planks have also been developed for CNC cutting too with plank ends puzzle fit together with a backing block epoxied to the backside. Other major longitudinal members like the stem, keel, chines and sheer clamp are to be of laminated Doug Fir. All members are to be epoxied together. Additional optimization and weight reduction could be accomplished if the builder were willing to use okume-skinned honeycomb panels for the cabin sole and seating.